Machine Details:

Technical Details:

-

Control:

-

Spindle Speed:10.500 rpm

-

Tool Holder:

-

Tool Capacity:12 x

-

X-Axis:550 mm

-

Y-Axis:300mm

-

Z-Axis:425 mm

Description:

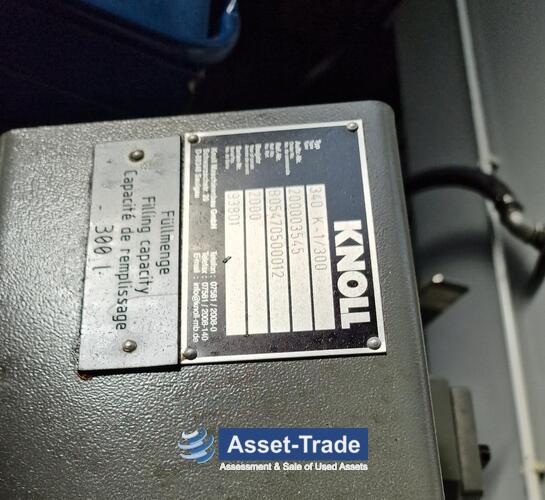

Used Chiron FZ 12W Magnum high Speed - Vertical machining center

The used CHIRON FZ 12 W MAGNUM is a high-speed machining center with a pendulum table, ideal for precise and fast machining processes. Equipped with a Fanuc 21i-M CNC control, this vertical machining center offers travel paths of 550 mm in the X-axis, 300 mm in the Y-axis and 425 mm in the Z-axis. With a rapid traverse speed of 30,000 mm/min and a spindle speed of up to 10,500 rpm, it delivers outstanding machining speeds and efficiency. CNC machining is optimized by a 12-position tool changer device.

CNC control Fanuc 21i-M

Technical data:

- Travels:

- X-way: 550 mm

- Y-way: 300 mm

- Z-way: 425 mm

- table size: (2x) 660 x 400 mm

- max. table load: 500 kg

- rapid traverse speed: 30000 mm/min

- tool changing device: 12 pos.

- tool change time chip-to-chip: 2,9 s

- spindle mounting: ISO 40

- spindle speeds: 20 - 10500 rpm

- spindle drive motor 5,5 kW

- Total power requirement: 15 kVA

- Weight: approx. 3590 kg

Do you want to produce quality and precision in cycles, at favorable unit costs? The machining centers of the 12 series combine these requirements and are among the best in their class in terms of speed, compact design and versatility of use. All models can be perfectly tailored to your requirements with high-tech modules - spindles and spindle systems, tool changing systems, table variants and additional automation.