Machine Details:

Technical Details:

-

Control:

-

Machine Hours:32.500 hrs.

-

Spindle Hours:14.500 hrs.

-

Spindle Speed:12.000 rpm

-

Tool Holder:

-

Tool Capacity:32 x

-

X-Axis:630 mm

-

Y-Axis:400mm

-

Z-Axis:360 mm

Description:

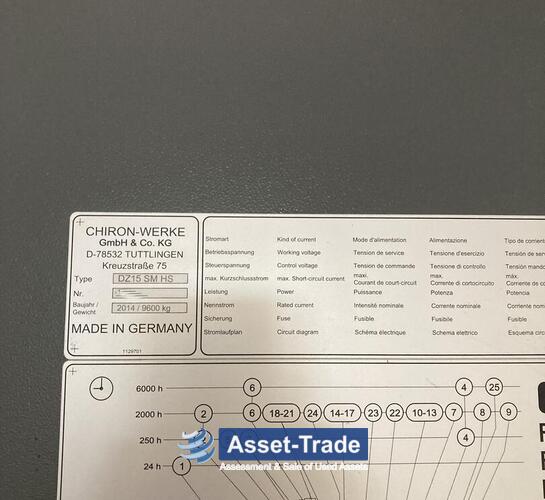

Used CHIRON DZ15 S Magnum high speed - vertical CNC machining centre.

3x pieces available : 1x 2013 & 2x 2014.

- CNC control : SIEMENS 840D solution line with 10,4" TFT colour screen.

- Operating hours approx. 32.500 AN / spindle 14.500 hours.

Technical data:

- Travels - Direct path measuring system in all axes:

- X-axis: 630 mm

- Y-axis: 400 mm

- Z-axis: 360 mm

- Rapid traverse speed: 75/ 75/ 75 m/min

- NC rotary table, type ATU 200 4th axis

- Repeat accuracy +/- 8

- Bridge dimension 800 mm

- Swivel radius 285 mm

- Face plate Ø 225 mm

- Main spindle drive with 2x AC motors:

- Speed each up to: 12,000 min-¹

- 9.5 kW at 100% ED

- 14.0 kW at 15% ED

- Torque:max. 90 Nm

- Spindle distance in: X-axis 320 mm

- Coolant system / IKZ: 70 bar in 7 different pressure stages

- Steel E335

- Drilling capacity: 2 x Ø 36 mm

- Thread cutting: 2 x M 24

- Milling capacity: 2 x 150 cm³/min

- Tool changer Automatic:

- Tool places: 2 x 32

- Tool shank: HSK-A 63 DIN 69893

- Tool Ø: max. 78 mm

- Tool-Ø with free neighbouring places: max. 140 mm

- Tool length: max. 300 mm

- Tool weight: max. 5.0 kg

- Tool change time: approx. 0.9 s (depending on control)

- Chip to chip time: approx. 2.4 s (depending on control)

- Mini handwheel

- Flush gun

- Chip conveyor: 320 l

- Extinguishing system Waterfog (Minimax)

- Machine preparation for central coolant system

- Suction connection

- Tub rinsing

- Coolant package

- Hydraulic connection for 200 bar

- Operating instructions

- Renishaw probe package OMP 40-2LS

- Monitoring system as well as

- MCIS DNC

- Remote diagnostics and teleservice

- V24 interface

- Universal interface RS 232C

- Machine colour:

- light grey according to NCS S1502-B

- blue according to NCS S2050-R80B

- basalt grey according to RAL 7012

- Mains connection:

- Supply voltage machine 3x400 Volt ± 10%

- Voltage socket 230 Volt ± 10%

- 30 kVA

CHIRON 15 Series:

The 15 Series Machining Centers are best in class for speed, compact design and reliability. They have huge reserves for highly productive grinding and thanks to their modular design, for example with several spindle and table versions, they can be configured to create the perfect individual solution. Choose them for consistently fast processing and high availability with low unit costs.

Single- and double-spindle machines can be equipped with a chain-type tool changer to process complex workpieces with many tools. Alternatively, the body tool changer is currently the fastest tool change system on the market, ideal for high precision machining of countersunk holes. The FZ/DZ 15 W with load changer for loading and unloading while the machine is running are experts in large quantities, as is the TZ 15 W with four powerful spindles and workpiece changer.

CHIRON 15 Highlights

- Fast, productive machining

- Reliable performance

- Compact machine layout

- Vertical traveling column

- Mineral casting machine bed

- High rigidity and thermal stability

- Dynamic direct drives and precision guides

- High running, positioning, and long-term precision

- Robust CHIRON rotary axes

- Fully enclosed working area, stainless steel covers

- Ideal chip flow directly into the chip feeder

- Ergonomic operating and loading concept

- Easy access to all units for servicing