This great Used ULMER SF40 REINECKER End profile grinding machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines » Tool Grinders machinery, or Contact us for further help.

Ref. No.:

1425-06201700

Products

Machine Details:

Technical Details:

-

Control:

Description:

This great Used ULMER SF40 REINECKER End profile grinding machine is unfortunately already Sold.

Discover further Metalworking » Grinding Machines » Tool Grinders machinery, or Contact us for further help.

Description

Buy used ULMER SF40 REINECKER | CNC end machining machine

If you are looking for a REINECKER end machining machine for the precise machining of cylindrical tools, then the used ULMER SF40 REINECKER is the ideal choice. Buying this end machining machine means investing in a powerful and reliable machine that efficiently handles a wide range of tool machining tasks. Whether for solid carbide, HSS or ceramics – the ULMER SF40 enables the machining of tips, chamfers and radii with the highest precision.

Technical data:

- Travel paths:

- X-axis 450 mm

- Z-axis 250 mm

- Resolution:

- X, Z-axis: 0.001 mm

- C-axis: 0.001º

- Rapid traverse X / Z: 15 / 30 m/min.

- Grinding spindle:

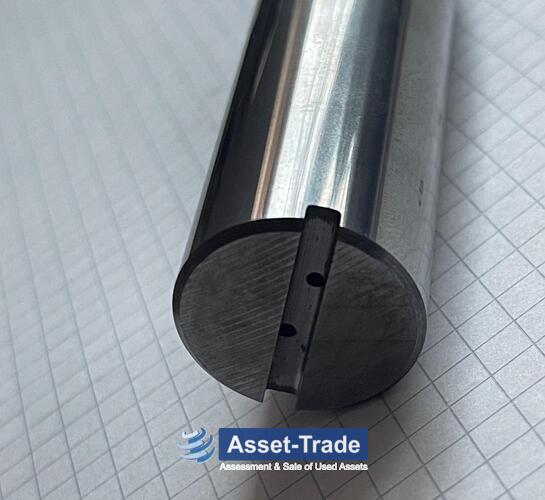

- Motor spindle ø x length: 140 x 300 mm

- Drive power S6: 14 kW / 170 Hz

- Speed continuously variable: 1,000 to 7,500 min-1 / 250 Hz

- Torque const.: 27 Nm to 5,000 min-1

- Grinding wheel ø max.: 350 mm

- Cutting speed: <140 m/s

- Workpiece spindle (C-axis):

- Mounting taper: SK50

- Speed max.: 3,000 min-1

- Max. torque: 28 Nm

- Dimensions WxDxH: 1,900 x 1,900 x 1,900 mm

- Accessories:

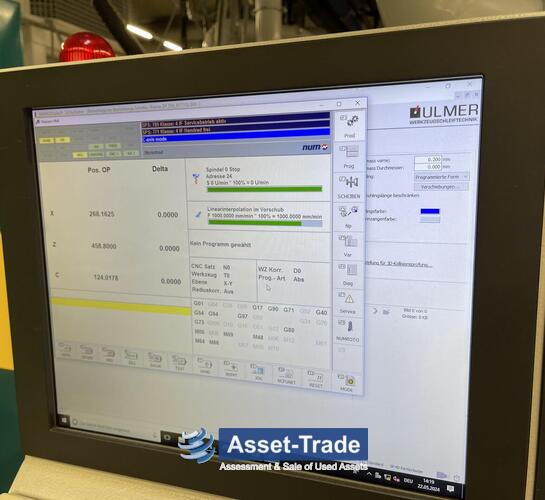

- Control and software NUMROTO Plus cylindrical grinding, loader, in-process measuring

- Probe for process-related measuring, including touch cycles

- 3D collision monitoring

- Interpolating C-axis

- Balancing system for grinding wheel in the machine

- Automatic chain loader

- Automatic bar feed

- Coolant pressure increase

- Oil pan

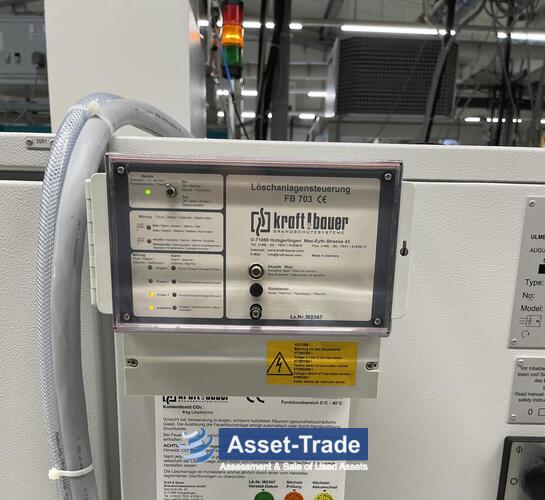

- K&B fire extinguishing system including fire damper

- Connections for central coolant supply and oil mist extraction

- Collet chuck W20 UP

- Hydro expansion chuck Schunk

- General:

- The machine is functional, in very good condition and

can be inspected by appointment.

- The machine is functional, in very good condition and

The ULMER end machining machine SF 40 REINECKER stands for:

- Creation of tips, chamfers, radii and their combination at the ends of cylindrical tools made of solid carbide, HSS and ceramic.

- Grinding unit with a liquid-cooled motor spindle.

- Variable spindle arrangement of the grinding unit for more flexibility, parallel or vertical.

- Up to four different grinding wheels can be mounted on one holder.

- Use of different chuck clamping systems.

- Measuring probe for recording the axial workpiece position and angular position of the cooling channels.

- Automatic loading devices are available as an option.

- NUM Flexium+ CNC control with powerful NUM DriveX drives and integrated NUM-Safe safety architecture.

Special features:

- The ULMER SF40 REINECKER is a high-precision tool grinding machine that offers high machining quality thanks to its powerful motor spindle and flexible spindle arrangement.

- With the option of mounting up to four different grinding wheels on one holder,