This great SCHNEEBERGER Gemini DMR - AWL 5-Axis CNC tool grinder is unfortunately already Sold.

Discover further Metalworking » Grinding Machines » Tool Grinders machinery, or Contact us for further help.

Machine Details:

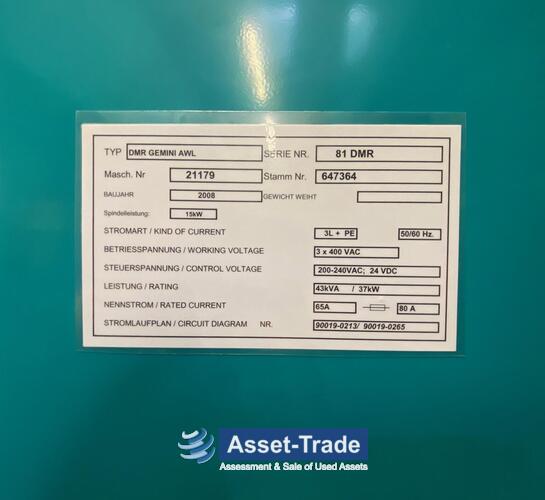

Technical Details:

-

Control:

Description:

This great SCHNEEBERGER Gemini DMR - AWL 5-Axis CNC tool grinder is unfortunately already Sold.

Discover further Metalworking » Grinding Machines » Tool Grinders machinery, or Contact us for further help.

Used SCHNEEBERGER Gemini DMR - AWL

5 axes CNC tool grinding machine

CNC control Fanuc 160i MB

Technical data

- Travels - Glass scales X, Y, Z

- X-axis 400 mm / 20’000 mm/mim

- Y-axis 300 mm / 5’000 mm/min

- Z-axis 280mm / 20’000 mm/min

- Resolution X/Y/Z : 0,0001 mm

- Centre height: 210 mm

- Spindle:

- Spindle speed: 10000 Rpm

- Drive power 15KW

- Grinding wheel holder: HSK 50

- Wheel diameter up to: 50-250 mm

- Grinding wheel changer 8 pieces

- Grinding wheel button

- Other

- CO2 fire extinguishing system

- 3D tracer

- Hydr. voltage ISO 50

- Network connection

- Interface to Zoller measuring devices

- Grinding software Standard-WZ

- Kennermetal-Hertel SE,TX,TF,Unidrill B9XX

- Sandvik

- Profile tools

- Woodworking tools

- 3D simulation

The SCHNEEBERG GEMINI DMR is a high-performance 5-axis CNC grinding machine with high performance and autonomy for the serial production of end mills, drills, profile tools, profile grinding of pinion cutters and hob peeling cutters, as well as production grinding tasks such as profile grinding and flat grinding.

The gemini is the 5-axis CNC grinding machine for the serial production of cutting tools. Complete processing around OD and face, up to 300 mm cutting length, diameter up to 300 mm, maximum workpiece length that can be clamped 400 mm.

Cutting tools such as end mills, ball nose cutters for mold making, high-performance drills, reamers and profile end mills are all part of the standard requirement.

There are specific software packages, grinding processes and clamping systems for the production of shaper cutters with highly dynamic segmented hob grinding, the regrinding of gear cutting tools, end mills, shaper cutters and bevel gear cutters.

CNC grinding of knives for the paper, foodstuffs and plastics industries, profile grinding, cylindrical grinding and surface grinding.