This great Used Wheel Rim Production Line by Leifeld & Ideal – Model Leifeld TF 650 is unfortunately already Sold.

Discover further Metalworking » Other Machines » Production Lines machinery, or Contact us for further help.

Machine Details:

Technical Details:

-

Control:

Description:

This great Used Wheel Rim Production Line by Leifeld & Ideal – Model Leifeld TF 650 is unfortunately already Sold.

Discover further Metalworking » Other Machines » Production Lines machinery, or Contact us for further help.

Used Wheel Rim Production Line by Leifeld & Ideal – Model Leifeld TF 650

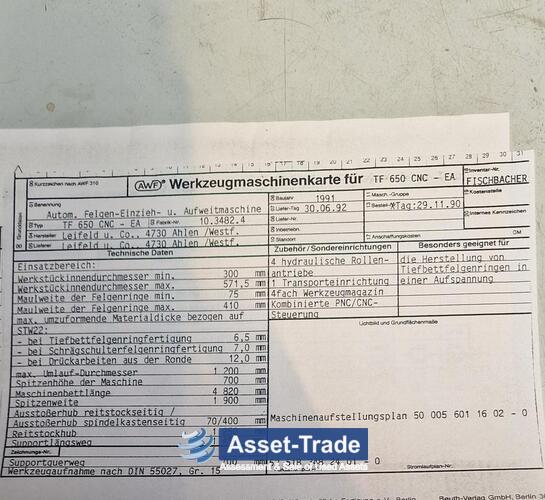

For sale is another complete production line for manufacturing steel wheel rims, centered around a Leifeld shrinking and expanding machine (Type TF 650 CNC). The line is complemented by a fully equipped welding cell from Ideal and all necessary peripheral systems. Thanks to detailed documentation, including the original machine data card, the line is precisely specified and perfectly suited for steel wheel rim producers.

This production line offers a proven and robust configuration to cover the entire manufacturing process, from sheet metal infeed to the finished wheel rim.

Used Leifeld wheel rim production line (TF 650) with Ideal welding system for sale. Complete production line for steel wheels, incl. bending machine & deburring unit.

Highlights of the Line

- Core Component: The renowned Leifeld TF 650 CNC shrinking and expanding machine (YOM 1992).

- Complete Welding Cell: Including an Ideal Welding System (AS220AF) and an Ideal Weld Seam Deburring Machine (EV0500).

- Comprehensive Peripherals: With a sheet metal loading station, bending machine, hydraulic power units, and a weld fume extractor.

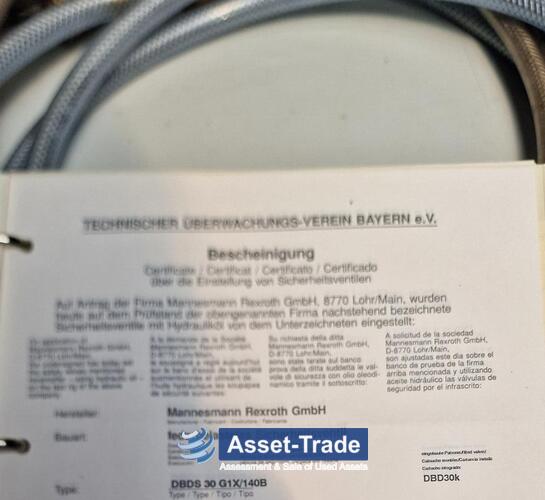

- Well-Documented: Original machine data card and technical documents are available.

- Includes Workstation: Comes with workshop equipment, a PC terminal, and a printer.

Detailed Technical Specifications

For further technical details, documentation, or to schedule an inspection, please do not hesitate to contact us.

This wheel rim production line represents an excellent opportunity to acquire a proven and comprehensive manufacturing capacity.