Machine Details:

Technical Details:

-

Control:

Description:

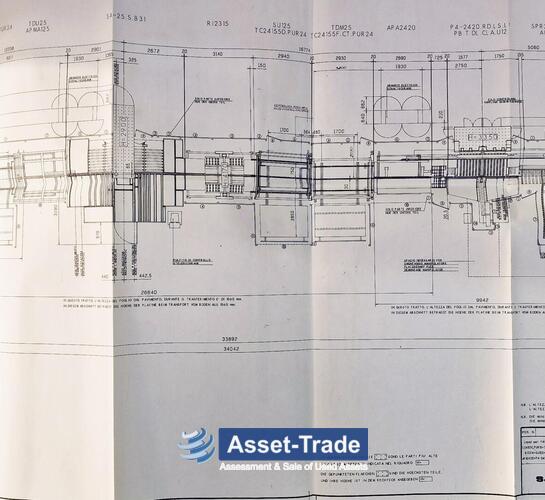

Used SALVAGNINI S4 + P4-2420 Panel Bender & Punching machine

Technical Data:

- Maximum length x width of incoming sheet: 2420 mm

- Minimum length x width of incoming sheet: 436x 130 mm

- Maximum diagonal of incoming sheet: 2220 mm

- Maximum bend height: 203 mm

- Maximum material thickness: 2.0 mm

- Minimum material thickness: 0.5 mm

- Loading: automatic / manual

- Carrying capacity 5000 kg

The Salvagnini S4 +P4 System are flexible lines for producing panels from packs of sheet metal. The punching, shearing and bending process are integrated to eliminate material handling. The S4+P4 System can also run as separate work cells. The intrinsic flexibility of the individual S4 and P4 System extends to the hole line.

Efficient production:

The production process from the raw material to the finished panel takes place on a single machining line. This offers concrete saving in terms of processing times, work in progress, space occupied, logistic costs and staff. the possibility of operating as integrated separate punching/Shearing and panel forming cells further increases production efficiency.

SALVAGNINI P4 bending unit

The Bending Unit of the P4 Panel Bender is the fruit of exclusive Salvagnini technology. It allows the bending angle to remain constant from one panel to the another and form one batch to another, for the same material and thickness. It also enables different thicknesses to be bent with the same tool.

The rigidity of the bending tools keeps the bent edge straight and constant along the edge of the sheet regardless of the length and thickness of the panel.

An unlimited number of up and down bends can be made without removing the panels from teh work surface.

SALVAGNINI P4 manipulator

The manipulator of the P4 Panel Bender handles the sheet automatically, rotating it by 90°, 180° or 270° or indeed my any other intermediate angle.

The notches other than the edges of the punched sheet are used as reference for positioning it. this obviously contributes to the excellent precision of the component produced, which is further guaranteed by totally accurate manipulator movements.

The SALVAGNINI P4-2420 is also equipped with a number of features that make it a very user-friendly machine, including:

- Easy-to-use touchscreen interface

- Integrated OPS software for managing production sequences

- Automatic tool changeover

- Zero-setup tooling

The machine is typically used to produce sheet metal components for a variety of industries, including:

- Automotive

- Aerospace

- HVAC

- Medical

- Retail