Description:

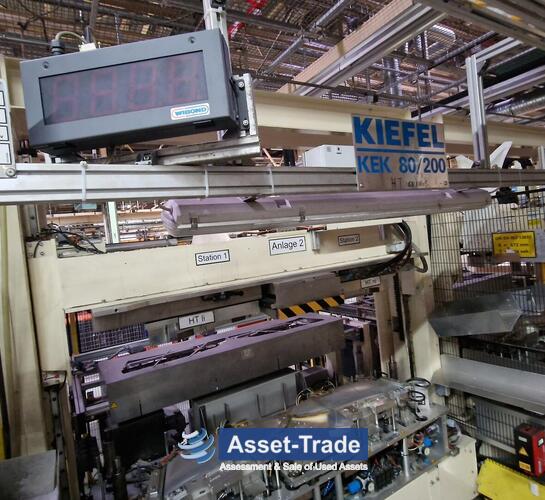

Used KIEFEL KEK-L-80/225 press laminating line automotive

CNC control: Siemens

Technical data:

- Max. press force: 25kn

- max press stroke top: 1000mm

- max usable area: 800 x 2000m

- Rated current: 110 A

- El. connected load: 76kVA

- Compressed air supply: 6 bar

- Air consumption / cycle: 90l @ 6 bar

- Cooling water connection: R3/8

- Dimensions: 6,3 x 3,6 x 2,5m

One of the main functions of the press laminator type KEK 80/225 is the placement of the decor for the interior door trim and its gluing with the carrier part. All individual processes and the actual lamination process are precisely coordinated with each other in an automated sequence. However, the manually onto the seam sword before moulding.

The operator places the decor with the upper side facing downwards. "The difficulty lies in the exact positioning of the decorative seam on the seam sword. of the decorative seam on the seam sword

Introducing the 2012 KIEFLE 80/225 automotive door panel machine - the ultimate solution for cost-effective and high-quality interior products. With its innovative Tailored Blank Laminating Technology (TBL), this machine is intelligently automated to deliver excellent quality at an economic price. The KIEFLE vacuum laminating machine operates completely automatically, without any operators. The KIEFLE machine’s innovative design reduces its overall footprint by 50%, making it a compact and efficient solution for your production needs. Don’t miss out on this opportunity to enhance your production process with the 2012 KIEFLE 80/225 automotive door panel machine.