Machine Details:

Technical Details:

-

Control:

Description:

Used MANTA paint for plastic parts

2k. Dosing type Merge Perfect designed for water-based paint 3 colors and 2 hardener with 2 Lackierrobotersystemen

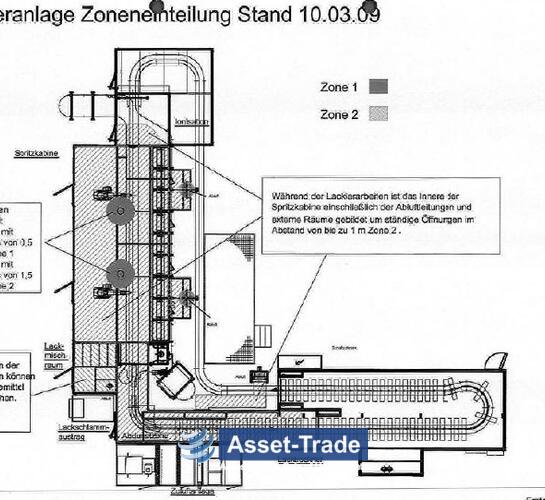

Operation in 2 zones.

Function ionizing station

In Inosierstation is the removal of dust and the surface by electrostatic discharge and blow the parts.

Discharge is by a high voltage generator and the ionisation (airlock).

The airlock performs 2 functions at the same time. It eliminates the electrostatic charge and removed the dust.

Of tandem electrodes contacting high exit velocity ions are mixed with a pressure jet. This electrically conductive air is - due to the alternating voltage of the mains frequency used - is submitted to positive and negative ions. This means that all electrostatic discharge (positive & negative) eliminated.

Specifications ionizing station

- Outside dimensions: LxWxH approx 2146 mm x 2253 mm x 3000 mm

- Airlock: Number 1 Long 150mm

The cabin air, and thus the passing of the workpiece to be sprayed paint mist from the cabin is sucked by the fan and passed over the washout.

The washout of the vortex is air scrubber, mist and water mix as a result of high air velocity intense.

Technical data of the paint booth

- Outside dimensions: LxWxH 9,000 mm x 4.454mm x 4.200mm

- Interior dimensions: LxWxH 8.800 mm x 3.494mm x 3.725mm

- Passage section width x height 500mm x 2.100mm

- Air sink rate 0.3m / s

- Exhaust fan

- Air Power 2x 13,000 m³ / h

- Power 2x 5.5 kW

- washout

- pump flow 120 m³ / h

- Motor power 4.0 kW

Specifications air conditioning

- Air supply for paint spray booths, flash-off zone

- supply air flow 30,000 m³ / h

- Power 18.5 kW

- 575 kW heating capacity

- air heating from -12 ° C to + 45 ° C

- type of heating steam

- Humidification

- Ventation conditions at +20 ° C and 50-60% RH

- Power humidity pump 5.5 KW

- Device insulation 40mm

- Pre-filter class G3