Machine Details:

Technical Details:

-

Control:

-

Machine Hours:50,000 hrs.

Description:

Used VOUMARD 200 CNC B-L6-T4-U2 Cylindrical grinding machine

- Estimated running time: 50.000 - 70.000 hrs.

- Control: Siemens 840Dsl

- 2018 General overhaul - scope of retrofit (carried out by ELSA retrofit GmbH)

- Converter for controlling HF spindles, power 20 kVA

- Interfaces to external units such as spindle cooling, belt filter, control panel, incl. gallows.

Technical data:

- Grinding diameter min.: 12 mm

- Grinding diameter max.: 200 mm

- Max. workpiece length: 600 mm

- Max. workpiece weight: 120 kg

- Swing diameter:

- Above the workpiece table : 230 mm

- In front of the workpiece table: 350 mm

- Axis movement:

- Longitudinal travel (Z-axis): 500 mm

- Transverse travel (X-axis): 120 mm

- Headstock (U-axis) 150 mm

- B-axis swivel range: -15 / + 2 °

- Resolution B-axis: 0,0001°

- Grinding headstock resolution: 0.001°.

- Feed rate:

- Z-axis n(longitudinal travel): 0 - 99.99 mm/min

- X-axis (cross travel): 0 - 99.99 mm/min

- Rapid traverse Z: 15 m/min

- Rapid traverse X: 5 m/min

- Spindles: 4 pcs:

- Max. speed (1x): 7500 rpm

- Max. speed (2x): 18000 rpm

- Speed max. (1x): 24000 rpm

- Grinding spindle motor: 4.3 / 4.8 kW

- Compressed air connection: 5 bar

- Connection 50 Hz: 3x 380 Volt

- Dressing device hydraulic

- Coolant device

- Paper filter system

- Extraction system

- Lighting

- Machine weight: approx. 4500 kg

The Voumard 200 CNC is a CNC-controlled high precision internal grinder with a 2 spindle turret. It is suitable for grinding complex internal shapes and is also capable of cylindrical and face grinding

Typical applications are grinding operations on parts for:

- Hydraulic components

- Spindles

- Bearings

- Gears

VOUMARD systems are suitable for a large variety of parts manufactured in large batches (like diesel common rail and hydraulics-pneumatics components) or low quantities (like high precision bearings and machines spindles components).

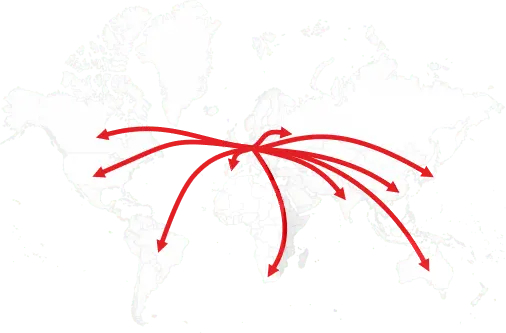

The VOUMARD machine range provides every customer with both high productivity and high flexibility grinding solutions. Our machines are appreciated worldwide and integrated in production lines or manufacturing workshops of market-leading companies in major industry segments like automotive, aerospace, bearing, tooling, and spindle manufacturing.