Ref. No.:

1443-10171512

Machine Details:

Technical Details:

-

Control:

-

Machine Hours:68.511 hrs.

-

Spindle Speed:10.000 rpm

-

Tool Holder:

-

Tool Capacity:80 x

-

X-Axis:650 mm

-

Y-Axis:650mm

-

Z-Axis:650 mm

Travels:

Description:

Description

Used HELLER MCT250 double spindle horizontal machining center with A-axis and 2 x B-axis

The used HELLER MCT 250 is a horizontal machining center with a double spindle that is designed for precise CNC machining. It offers 5 NC axes and a generous work area with a travel of 650 mm in the X, Y and Z axes. With the Siemens 840D CNC control and a new spindle from 2012, the machine offers high performance. Precision machining is supported by fast tool changes and a 2x40-fold tool magazine. Ideal for versatile applications in the machine tool industry.

- CNC control: Siemens 840D

- New spindle in 2012

Technical data:

WORKING AREA:

- Travel

- X-axis 650 mm

- Y-axis 650 mm

- Z-axis 650 mm

- Number of NC axes 5

TABLE:

- Rotatability 360 °

- Positionability 0.001 ° rotation speed 30 / min swiveling 210 °

- Positionability 0.001 ° rotation speed 10 / min

WORKPIECE / HEAD

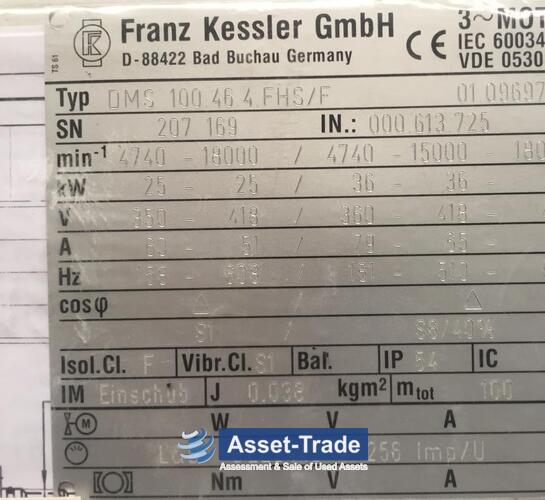

- Spindle speed 45 - 18000 / min Kessler

- Spindle diameter 80 mm tool holder

- Drive power (max.) 38 kW

- Spindle power (continuous) 25 kW

- Torque (max.) 132 Nm

The following restrictions apply:

- Maximum permissible weight of the moment absorbed by the gripping tool. 1 000 Ncm

- Maximum permissible tool weight 12 daN

- Fast tool change up to a tool weight of 3 daN

Axis drives

- Feed of 1 mm/min

- Feed speed up to 60000 mm/min

- Rapid traverse speed 60000 mm/min

TOOL MAGAZINE

- Number of tool positions 2x40

- Tool diameter max. 70 mm

- Free adjacent position 163 mm

- Tool length max. 300 mm

- Tool change time 3.2 s

DIMENSIONS / WEIGHTS

- Total weight approx. 16000 kg