Machine Details:

Technical Details:

-

Control:

-

Machine Hours:0 hrs.

Description:

Brand new HERKULES WSE 180 x 1500 CNC roll grinding machine

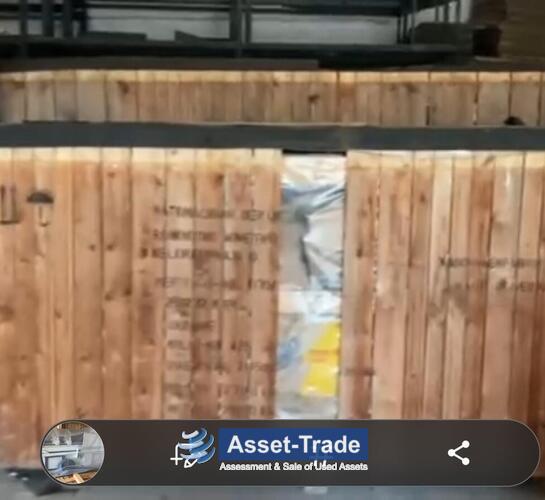

The brand new HERKULES WSE 180 x 1500 CNC roll grinding machine is still in the original wooden packaging and has zero operating hours. Buying this new roller grinding machine is an excellent choice for companies that want to carry out precise roller machining.

Still in original wooden packaging

Zero operating hours

Technical data:

- Power: 70 kW

- Working area:

- Max. grinding diameter: 360 mm

- Min. grinding diameter: 0 mm

- Max. center distance: 1500 mm

- Max. roller weight in lunettes: 700 kg

- Headstock

- Roller speeds, continuously adjustable: 16-160 rpm

- Transistor-controlled three-phase servo motor max. torque: 27 Nm

- Tailstock

- with manually operated adjustment device: for longitudinal movement of the tailstock on the machine table

- with mechanical, conical clamping elements: for clamping the tailstock in any position

- Grinding table

- Travel speed, continuously adjustable: 50-3000 mm/min

- Frequency-controlled three-phase servo drive: 14 Nm

- Guideway lubrication: combined hydrodynamic/forced lubrication to avoid the typical floating effects of hydrostatic lubrication

The following grinding wheel feed types are included:

1. Motorized rapid feed (X-axis): 400 mm/min

2. Motorized fine feed (X-axis) exact: 0.01mm

3. Automatic feed in the reversing points (X-axis), preselectable: 0.01 -0.09 mm

3.' Automatic feed in the reversing points (F-axis), preselectable 0.001 -0.01 mm

4. Continuous feed to compensate for grinding wheel wear, for working with constant power (X-axis), preselectable 0.01 -0.2 mm/min

5. Automatic feed limitation with automatic feed shutdown, digital, when preselected values are reached

6. Automatic attachment of the wheel to the roller with X-axis feed,

shutdown and automatic initiation of the Z-axis feed.

Including:

Automatic safety retraction of the

Disk at preselected ampere levels

Overload overspeed

Power failure

7. Manual microfeed

Accuracy: 0.001 mm

8.

a) Hollow and bellows grinding option

b) light

particularly at the ends of the barrel for pressure

relief in the rolling mill: 1 mm on diameter

Cone grinding

9. Reset device for automatic repositioning of the grinding disc on the roller

after a Grinding process interruption

(measuring e.g.) with a restart accuracy of: 0.001 mm

The Herkules WSE 180 CNC roller grinding machine offers continuously adjustable roller speeds of 16-160 rpm and a frequency-controlled servo drive unit for precise grinding processes. The machine is ideally suited for the roller grinding machine for precision machining and offers a high level of flexibility for various grinding techniques such as hollow, conical and ball grinding.

The Herkules roller grinding machine used not only offers a high level of precision when machining rollers, but also an automatic grinding process setting that ensures consistent performance. With an accurate microfeed of 0.001 mm and automatic feed at the reversing points, this CNC roll grinding machine enables extremely precise machining with high productivity.

For companies looking to buy a new roll grinding machine or a used roll grinding machine for precision machining, this machine is an excellent solution. It is available in both its original packaging and in brand new condition and can be viewed by appointment.